I was curious about the North American-specific adaptations the VNL had compared to the previous global cab. For one thing, they’re not speed-limited, unlike heavy-duty trucks in Europe, which aren’t allowed to go faster than 56 mph (90 km/h). “So we had to take that in consideration in the design,” explained Stadler.

That meant a focus on reducing drag. “We made sure that design of this truck is fully aero’d up, as much as we can possibly put together on this truck. And we take the learnings that we got from Super Truck and Super Truck II to apply those to this design,” Stadler said. For example, there are cab-side fairings that connect to the trailer and keep the airflow from detaching between the tractor and trailer that boost overall fuel efficiency by 7 percent.

Credit:

Volvo Trucks

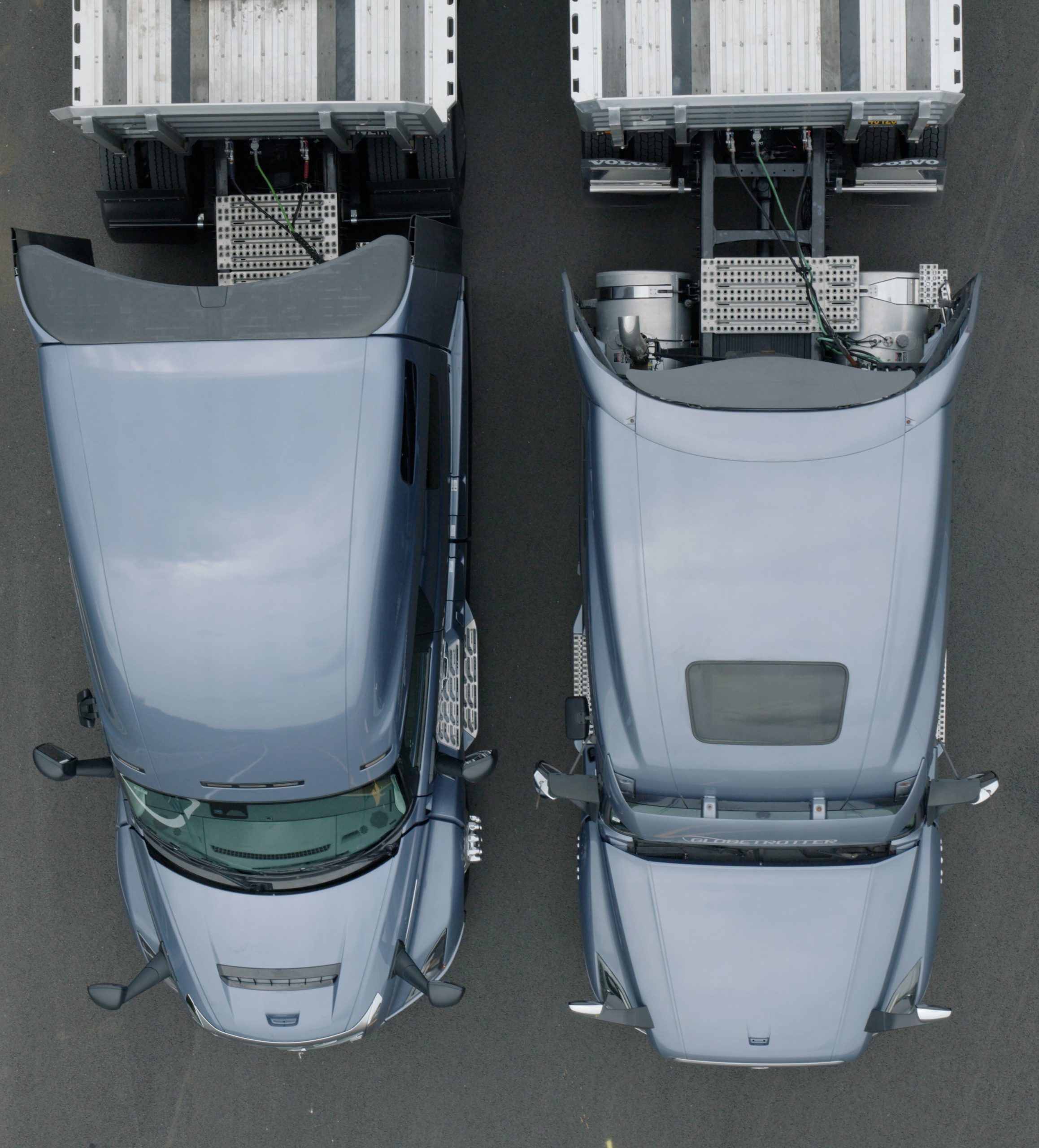

Keeping the air attached to the trailer after it leaves the cab is critical for reducing drag.

Credit:

Volvo Trucks

The company eschewed going for something weird like a center-mounted seat or round windshield like some aerodynamic truck concepts in the past. Partly, that’s due to market acceptance—if it looks too weird, the companies that buy fleets of Class 8 trucks will take their orders somewhere else.

“When we started with the design of the cab—and especially the frontal area, because that’s 70 percent of the aerodynamics of the frontal area of the vehicle—we found that this wedge cab shape and a highly raked windshield were key determinants in improving the aerodynamics,” explained Brandis. As a result, VNL has a narrower hood than Volvo’s previous cab, and there’s much more attention to detail closing up gaps between panels.

Other details from Super Truck II didn’t make it to VNL, like the driver’s door. On the research project machine, this was behind the driver, entering the truck into the sleeper area rather than the cockpit.

“We talked to drivers and they said, ‘You know, that’s neat, but it’s not practical for us. We get in and out of the truck, especially in regional day cab applications, 30, 40, 50 times a day. That won’t work.’ So when you’re doing a one-off, you can do these concepts without necessarily taking them all to production. But the overall shape, dimensions, the technologies, the bonding of the windshield, many of those things are directly carried over into the new VNL,” Brandis said.